Explain Different Types of Plant Layout

Four Main Types of Plant Layout 1. B Functional or Process Layout.

It is a floor plan of the physical facilities which are used in production.

. Types of Layouts in industries - Generally there are 5 types of layouts that are widely in usage by industries They are - 1. Some of the ways in which plant layout contributes to safety and loss prevention SLP are. Plant layout is a crucial factor in the economics and safety of process plants.

Segregation of different risks 2. It is also known as functional layout. The Plant Layout has been defined by various authorities as follows.

This type of layout is very popular in mass production. The following are the popular types of plant layout. C Fixed Position Layout.

Disadvantages OF CELL Layout Can be costly to rearrange existing layout Can need more plant and equipment Can give lower utilization of plant 31. It is the configuration of departments work centers and equipment in the conversion process. Plant layout refers to the physical arrangement of production facilities.

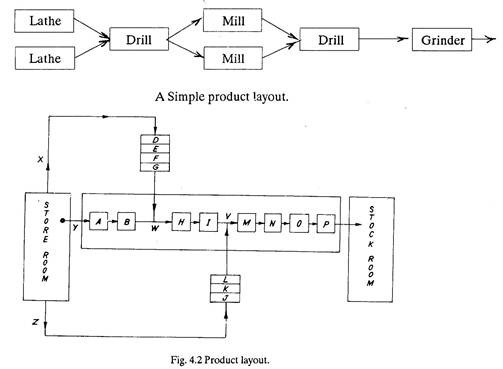

If all the processing equipment and machines are arranged according to the sequence of. Process or Functional Layout. The product layout process layout hybrid layout cellular layout are explained with examples.

Process layout means the layout which group resources based on the similar processes or functions. Plant Layout in Operation Management. Product or Line Layout.

Types of Plant Layout. The process layout is particularly useful where low volume of production is. There are different types of work equipment layouts WEL for different types of products 15.

A Line or Product Layout. MIXED Layout Also called as Hybrid layouts Uses the combination of either some or. Types of layout There are mainly four types of plant layout.

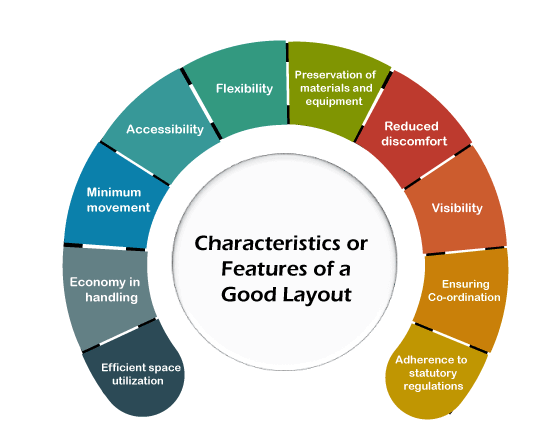

When planning WELs in production MH is often only. They are front engine rear wheel drive Rear engine rear wheel drive front engine front wheel drive and four wheel drive which are discussed below 1. It ideally involves the allocation of space and the arrangement of equipment in such a manner that overall operating Costs are minimized JL.

In product layout the equipment or assembly work stations are arranged according to the progressive. An entrepreneur must possess an expertise to lay down a proper layout for new or existing plants. 734 TYPES OF LAYOUT As discussed so far the plant layout facilitates the arrangement of machines equipment and other physical facilities in a planned manner within the factory premises.

The specliazed deparatment works for all type of production. A process layout is used in contexts where many different items are produced in small quantities. Each layout is explained in brief in the following paragraphs.

Product layout is considered a costly layout because there might be duplication of machines of similar types required for different production lines due to the arrangement of machines according to the sequence of operations. The main feature of this type of layout is that similar machines or similar kind of processes are kept in a group in a deparatment. Following is an account of the various types of plant layout.

Two basic plans of the arrangement of manufacturing facilities are product layout and process layout. Types of Plant Layout. It differs from plant to plant from location to location.

A Product Layout or Line Layout. The presentation ends with the briefing on the various types of transport. A Line or Product Layout.

Material handling is also discussed were the various principals of material handling are elaborated in detail. Product layout creates monotony because of the repetitive type of work of workers. Plant Layout Types Objectives Principles Advantages 1.

This presentation gives the entire picture about plant layout and its types. In fixed position plant layout the product by virtue of its bulk or weight remains at one. Rear wheel drive places the engine in the front of the vehicle and the driven wheels are located at the rear a configuration known as front-engine rear-wheel drive layout.

Front Engine Rear Wheel Drive. Definitions of Plant Layout. Keeping in view the type of industry and volume of production there can be following methods of layout.

1 Process layout 2 Product layout 3 Combined layout 4 Static product layout or Project layout 5 Cellular layout 6 Job Shop layout. There are four types of layout. There are four basic types of layouts.

The only other alternative is a combination of product and process layouts in the same plant. It is also called functional layout. A Product or line layout b Process or functional layout c Fixed position or location layout d Combined or group layout a Product or Line layout.

Fixed Position Layout Let us know study of each layout. This type of layout can be found in companies that use intermittent processing systems. Minimization of vulnerable piping 3.

Four Main Types Of Plant Layout

5 Main Types Of Plant Layout Industries

Mh004 Plant Layout Principles Of Plant Layout Types Of Layout Youtube

No comments for "Explain Different Types of Plant Layout"

Post a Comment